Product

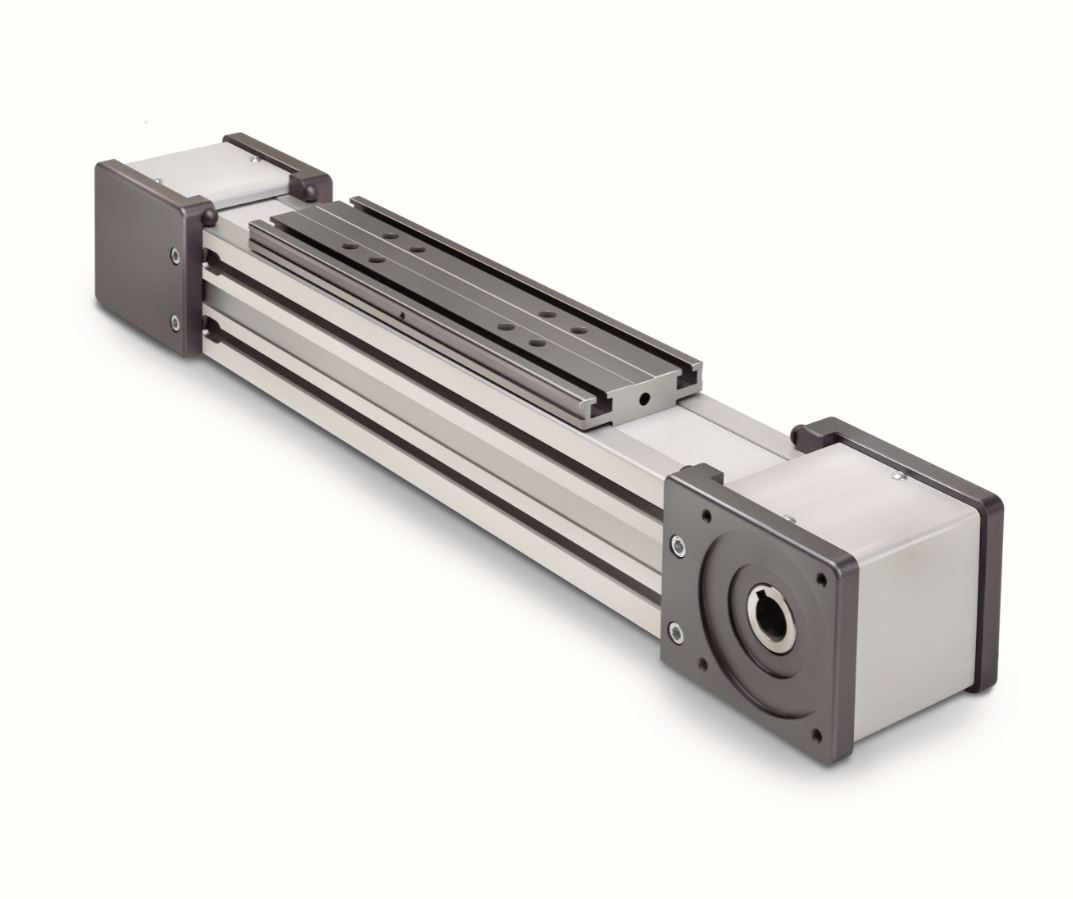

Module linéaire AGORA Technique

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

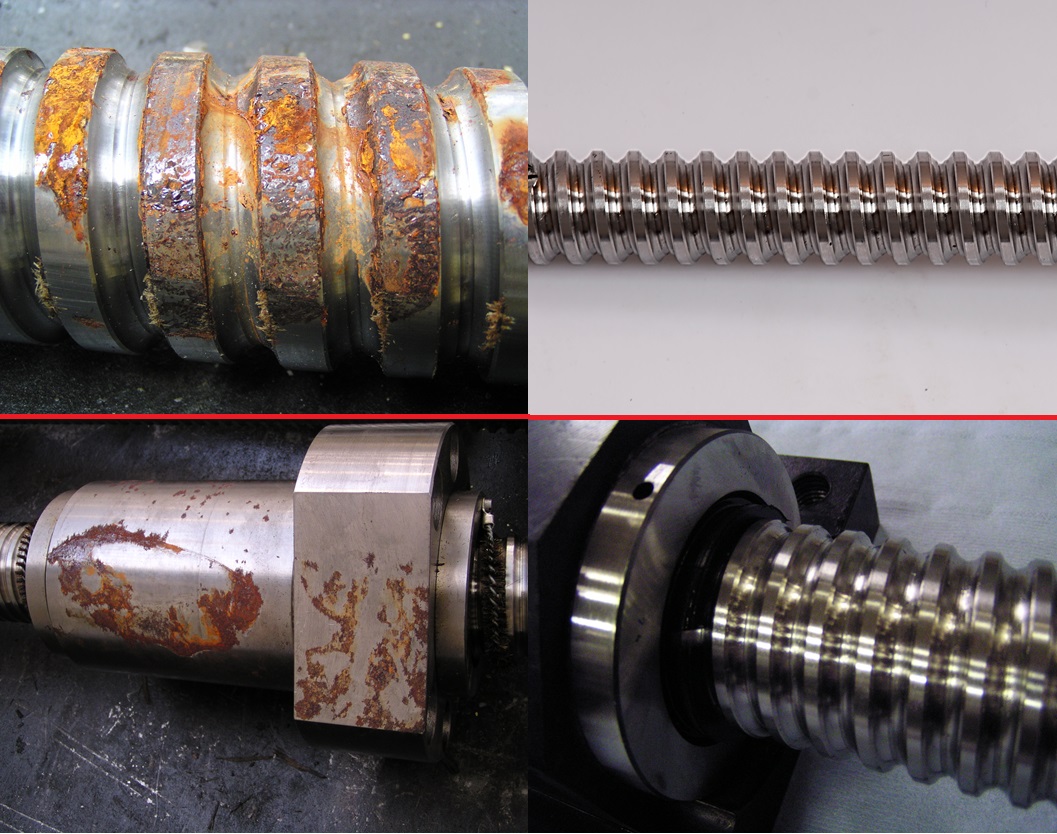

Repair and services The company KULIČKOVÉ ŠROUBY KUŘIM, a.s. provides repairs and overhaul of ball screws from its own production program and such produced by foreign ball screw producers. Those repairs are exclusively done in the company’s premises, where precise measurement and evaluation of the condition of the ball screws is being provided, thus offering an optimal solution for the customer. We offer also full-value replacement of the worn, unreparable ball screws, manufactured by any ball screw producer, with ball screws newly produced in our company. KSK offers: Overhaul an repairs of ball and trapezoidal screws manufactured by our company Overhaul an repairs of ball and trapezoidal screws manufactured by other producers Functionality renovation and preload setting, alternatively backlash reduction of the nut Full value replacement of worn screws with new ones, produced on basis of delivered sample Emergency repairs of ball and trapezoidal screws in short terms Repair and services : www.ks-kurim.cz/en/services/repair-and-services/

-

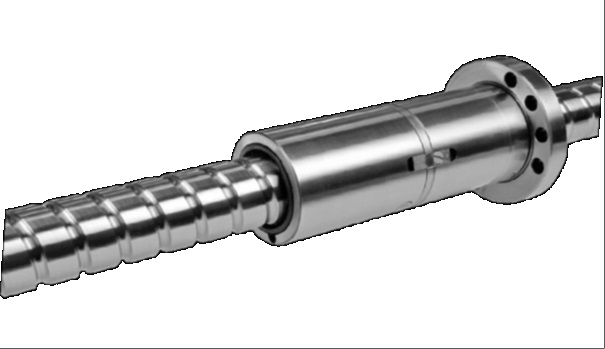

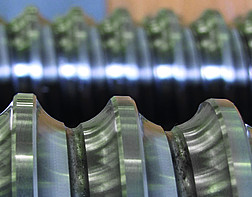

High-speed ball screws New technologies bring essential changes in the requirements for machine tools especially concerning rotational speed of the working spindle (up to 50,000 rpm), spindle output (15÷60 kW), linear working speed (10÷30 m.min-1) and linear high-speed (40÷80 m.min-1). In order to achieve the above mentioned parameters engineers are forced to use linear motors or high-speed ball screws. The linear motors have high cost and their high electromagnetic field often causes complications for the machine tool builders. This is why the cheaper and technically sufficient high-speed ball screws are more widely spread. In them the thread pitch P equals their diameter Do and they can be run at high rotational speeds n (Do multiplied by n can be up to 125,000). For this type of ball screws the following nut types are available: Single preloaded nuts by difference between thread leads Nuts with patented external ball recirculation system Usually nuts with flangeCharacteristics: Precise ground positioning screws High pitches up to the size equal to their nominal diameter, two-start and four-start screws Standard geometric and working accuracy, service life and load capacities according to DIN ISO 3408 Delivered with customized preloadTechnical parameters: Diameters from 16 to 50 mm Pitches from 15 to 50 mm, thread lengths to 2 m Thread lengths over 2 m can be supplied in single-start design with segments Accuracy class IT1 and IT3 Do×n = 125,000, efficiency 94–97% (according to thread pitch and lubricant) Minimum strength of the shaft material Rm= 650MPa, functional surfaces of the shaft and nut hardened to 58-60HRC Working temperature -40 to +80°C (according to lubricant type) Lubricants with high viscosity are recommendedApplications: Machine tools Positioning mechanisms Example of designation: K40×40 – 1.5+1.5/APVR HS/3 (ball screw with diameter 40 mm, with right hand two-start pitch 40 mm, with 1.5 working threads, preloaded nut type APVR with flange type 3) High-speed ball screws : www.ks-kurim.cz/en/ball-screws/high-speed-ball-screws/

-

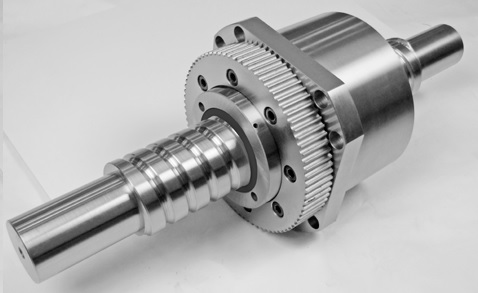

Ball screws with a driven nut The ball screw with a driven nut is a construction unit designed for direct mounting into the support of the machine and for connection to the drive through a gearwheel, or a wheel for cogged belts. In the RMV variant readymade bearings are inserted between the nut and the housing, whilst in the RMI variant the bearing tracks are produced directly on the outer surface of the nut and the balls recirculate between the nut and the housing. The nut is preset for driving gearwheel mounting. The preloaded bearings have been selected with respect to the load-carrying capacity of the nut. The precision class of the bearings also complies with the precision class of the ball screw. This compact unit is filled with a permanent grease filling and possible additional lubrication of the nut and the bearings is provided manually through a greasing hole, which can be adapted according to the requirements of the customer. This assembly is usually based on a double preloaded nut with segment recirculation system of the balls in a hole drilled lengthwise in the body of the nut above the thread. In the case of a double thread shaft the preload can be done by displacement of the run within each nut, resulting in an extremely compact unit for high speed and acceleration. This solution provides machine tool builders with an opportunity to use an ecological and energy saving drive alternative in comparison with the standard shaft drive, which negatively influences the power consumption for its own rotation. It reflects the demands of the new European legislation being prepared in this regard. Characteristics: Compact construction unit for direct drive of the nut Possibility of nut preload Standard geometric and working accuracy according to DIN ISO 3408Technical parameters: Diameters from 50 to 80 mm Recommended pitch from 20 to 32 mm Precision class from IT1 to IT5 Do×n = 100,000, efficiency 95–97% (according to the thread pitch and lubricant) Minimum strength of the shaft material Rm = 650MPa, functional surfaces of the shaft and nut hardened to 58–60HRC Working temperature -20 to +60°CVariants of performance: Preloading by the difference between thread leads used in the two-start ball screws allows shortening of the nut Use of a single non-preloaded nut also allows shortening of the nutApplications: Machine tools Transporting mechanisms Substitution of racks Long actuation assemblies Example of designation: RMV K50x25 – 4/ (driven nut with inserted bearings for ball screw with diameter 50 mm with pitch 25 mm and 4 working threads), or RMI K50×32 -4/ (driven nut with integrated bearings for ball screw with diameter of 50 mm with pitch 32 mm and 4 working threads). Ball screws with a driven nut : www.ks-kurim.cz/en/ball-screws/ball-screws-with-a-driven-nut/

-